Anionic Polyacrylamide Emulsion(APAM Emulsion)

Anionic polyacrylamide emulsion (033) produced by inverse emulsion method. It is soluble easily, various chemical reactions can be performed. It can be used as flocculants, adhensives, enhancer, surfactants, antistatics agent and sludge dewatering etc, widely used in oil recovery, textile, papermaking, medicine, sugar, coal washing, metallurgy and other industries wastewater treatment and sludge dewatering.

Product Description

Specifications

| Model | Molecular Weight

(millions) |

Hydrolysis degree | Solid content | Appearance | PH Value | Monomer Residual% | Involving time |

| 033 | 10-20 (adjustable) | 20-30

(adjustable) |

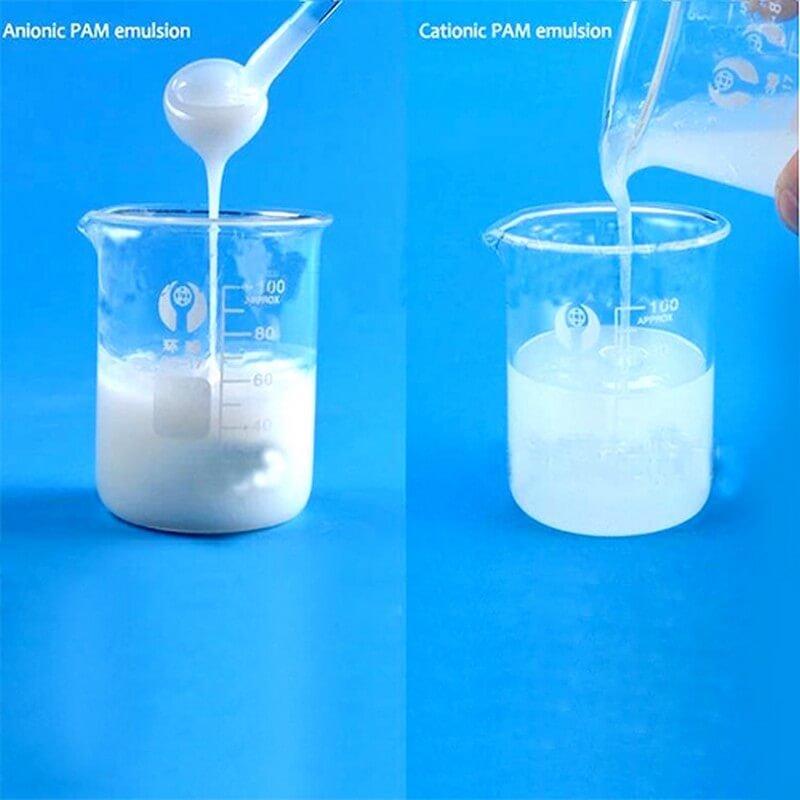

≥30 | White emulsion | 4-11 | ≤0.05 | ≤3 |

| 038 | 10-20 (adjustable) | 30-40

(adjustable) |

|||||

| 035 | 8-12

(adjustable) |

20-30

(adjustable) |

≥18 |

Main usage

High Polymer Emulsion:

This product is formed by emulsion polymerization in normal temperature, molecular, weight can be reached at 20million, strong coating and inhibition will formed by long chain.

Dissolving time will be very short. Normally within 2 minutes will be dissolved completely with none floating agglomeration, utilization will be 100%, drilling will be timely treated.

As it’s high molecular weight and high agglomeration, dosage will be comparatively small, normally 1-2‰ within25g/L will be satisfied.

Certain percentage of positive group will be added to enhance clay adsorption force, suppressed ion will be released to strengthen anti-collapse effect.

Non-toxic and non-fluorescent, it is suitable for drilling and environment drilling.

Industrial wasterwater treatment: Especially for the treatment of wastewater containing suspended particles, coarse and high concentrated particles with positive charges and water PH is neutral or alkaline. Most effective for wastewater treatment of ion and steel plant, electroplate factory, metallurgy and coal washing.

Drinking water treatment: Many water plants in China come from river water, which contains large sum of sediment and mineral, very turbid. After precipitation and filtration, it still can not meet the requirements. Flocculant is needed. Water plants used to use inorganic flocculants, but large additive amount is required, better effectiveness can be achieved with little dosage.

Papermaking addtives: Can be used for caustic soda’s clarification. Used as retention aid, filter aid, reinforcing agent for wet and dry paper.

Clarifying agent in sugar refining industry.

Additives and adhesives in aquatic product feedstuff.

Packaging and Storage

Packaging: 25kg plastic bucket or 1000kg plastic bucket or as required. Product should be stocked in cool, dry place and temperature between 10℃-30℃. Valid time will be 6months.